All Categories

Featured

Table of Contents

- – Motorhome Repair Shop Orange, CA

- – OCRV Center

- – Rv Service And Repair Near Me Orange, CA

- – Motorhome Repair Service Orange, CA

- – Rv Mechanics Near Me Orange, CA

- – Full Service Rv Repair Near Me Orange, CA

- – Best Rv Repair Near Me Orange, CA

- – Rv Generator Repair Orange, CA

- – Rv Ceiling Repair Orange, CA

- – Motorhome Repair Shops Orange, CA

- – Rv Repair Service Near Me Orange, CA

- – Rv Delamination Repair Near Me Orange, CA

- – Rv Repair Service Near Me Orange, CA

- – OCRV Center

Motorhome Repair Shop Orange, CA

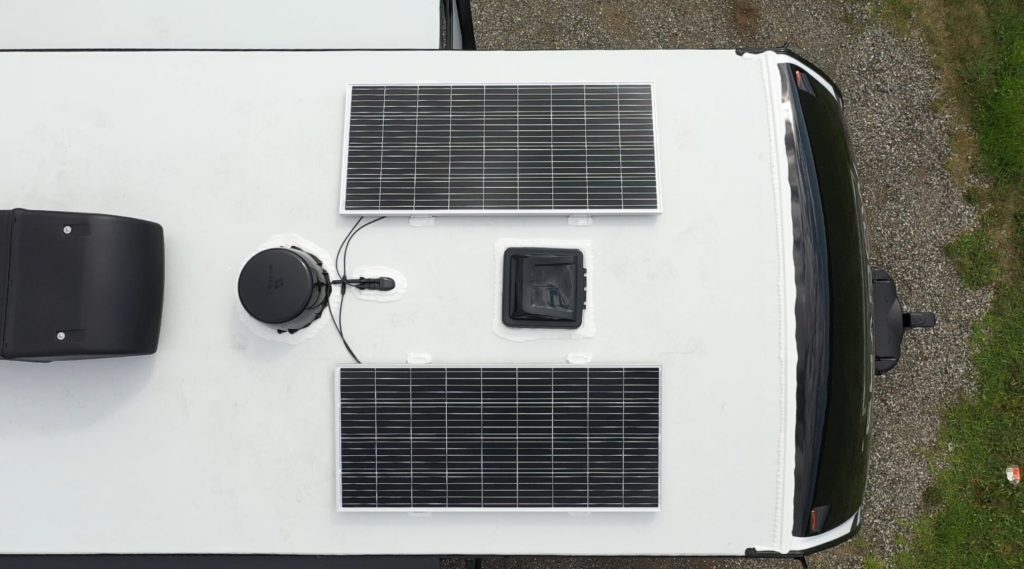

A 1000W inverter would certainly be adequate for a lot of motor home needs.: Pure sine wave inverters are best for sensitive electronics, while changed sine wave inverters are more affordable and sufficient for basic needs.: Secures the solar panels to your RV roof.: You can utilize a mounting kit or pick individual installing brackets, depending on the panel dimension and your recreational vehicle's roof covering.

: MC4 connectors for the solar panel circuitry and battery terminals for attaching the batteries to the system. The ideal area is generally a flat, unshaded location on the roof of your Recreational vehicle.

: For a more safe mounting, you can make use of roofing braces made for photovoltaic panels. Guarantee the placing equipment is suitable with your panel kind and the roofing system product of your recreational vehicle (Orange Motorhome Repair Shop). If you are utilizing brackets, drill little holes for the installing screws, making sure to seal them appropriately to avoid leakages

Ensure the electrical wiring is shielded from the aspects and safeguarded to the roofing to stop damage from wind or road vibrations. Locate a trendy, dry, and conveniently accessible location for the fee controller, normally near the battery bank. This will certainly reduce cord size and prospective power loss. Link the cost controller to both the solar panels (input) and the batteries (outcome).

Rv Service And Repair Near Me Orange, CA

A lot of RV planetary systems make use of 12V systems, so you'll likely wire the batteries in parallel.: Connect the positive terminals of the batteries with each other and the negative terminals with each other. Then link the financial institution to the fee controller. Pick an area for the inverter where it will certainly be well-ventilated and protected from the elements.

Then, cord the inverter's AC output to your recreational vehicle's electric panel, which powers your a/c tools (refrigerator, lights, etc). As soon as every little thing is connected, it's time to examine your RV solar system.: See to it it's charging the batteries effectively and the system is operating as expected.: Make use of a multimeter to examine battery voltage and ensure it's within the suggested range.

Motorhome Repair Service Orange, CA

Begin with tiny gadgets and progressively raise to larger ones like the fridge or air conditioner.: on a regular basis to ensure they are devoid of dust, dust, and debris.: Routinely examine battery voltage and fee levels to prevent over-discharging.: Inspect all circuitry and links periodically for wear, rust, or loosened links.

This training course is designed for the RV Specialist, Recreational Vehicle Examiner, or motor home owner that has an interest in solar energy equipment for the recreational vehicle. Pupils progress evaluation, diagnostic, and fixing skills of solar energy as it connects to motor home procedures. Trainees will certainly find out how to choose, install, operate, and keep solar power as well as just how to isolate and repair solar equipment problems.

Rv Mechanics Near Me Orange, CA

Solar Panel Install- Chaos, Kiddos & Harmony In the last few years, RVing has actually become progressively much more popular. The choices of where to stay have actually come to be vast open for RVers. Not only do you have options to remain at recreational vehicle Parks and Motor Home Resorts, being off the grid or boondocking has become an extra traditional option and much less terrifying.

A terrific solution is solar energy systems, unlike gas powered generators, solar energy a solar energy system is just that, a system. It is greater than just the 2 primary elements of batteries and panels. There are 5 standard components to a solar power system which is laid out listed below.

Full Service Rv Repair Near Me Orange, CA

Chances are you will require an inverter. The transfer switch is an elegant name to change between inverter power (solar power) and straight connect (referred to as it's maritime name of "coast power"). This switch makes sure that power is coming from one resource and not both at any type of provided time. The great news is, a lot of the time the inverter additionally consists of a transfer switch, so extra elements might not be needed.

Similar to the batteries in your TV remote or youngster's playthings, they keep power and deliver it when you require it. The distinction below is, depending upon what you require power for, you require a whole lot even more power than the TV remote. There are 3 major kinds of batteries: LifePO4 Lithium, AGM (Lead Acid), and Flooded Cell (Lead Acid).

Install a fuse or breaker on cords coming from the photovoltaic panels to the fee controller. See to it it is just slightly larger than the rated current on controller. This will activate the fuse in instance of a rise, which is far better than frying the entire system. Do not attach photovoltaic panels to charge controller until action 9.

Mount your inverter near the batteries and maintain it away from warm sources or any other dangerous substances (corrosive). It is suggested that you make use of 120 Thermal Circuit breaker for each battery.

Best Rv Repair Near Me Orange, CA

From the solar panels all the way to the battery links. Make certain you cover the solar panels to guarantee no electrical energy is being gotten right into the system.

Delight in the remarkable power of the Sunlight! Being able to have a solar energy system is a video game changer. It opens up a liberty that you would certainly or else not have. When looking at systems ask around and do your study. Batteries play an intricate role on exactly how lengthy you can stay and play in these remote places.

As soon as the planetary system establishes that your house batteries are adequately charged, it will certainly then direct some of that power to the chassis battery. To establish the length of time your recreational vehicle's solar cell bank will certainly last, we make use of a simple mathematics formula(start seeing at the 2:06 mark) that involves: recognizing your batteries' amp hours wiring them in series and identical transforming that final number to watt hours given that many products that utilize your battery power are gauged in electrical power developing a safe usage array that will not harm your batteries Once you've established this total watt hours number, separate into it using the wattage amounts from the lights, devices, and other recreational vehicle services you'll be making use of.

These solar panels are made to catch sunshine and transform it right into functional electrical power that can be used to charge batteries, run devices, and offer energy for various features within the RV. The energy produced by the photovoltaic panels can be saved in batteries, permitting recreational vehicle owners to have a sustainable and eco-friendly resource of power also when they're not linked to traditional electric outlets.

Rv Generator Repair Orange, CA

Deep cycle batteries store the power gathered by the solar panels. This includes brackets, mounts, and clamps to firmly affix solar panels to the Recreational vehicle's roofing system.

From monocrystalline to polycrystalline, thin-film to versatile panels, there's a wide-range of solar energy alternatives to fit your details demands. When choosing the perfect solar panel for your camper, monocrystalline solar panels stick out as a prominent and super-efficient option. These panels are crafted from a solitary crystal structure, making them extremely effective in transforming sunshine right into usable power.

Rv Ceiling Repair Orange, CA

: Inflexible panels are built with a strong framework and safety glass cover, making them sturdy and ideal for fixed installments. They are frequently placed on the level roofing system of a RV, guaranteeing security and optimal power manufacturing. Adaptable panels, made to bend and adjust, are ideal for rounded motor home surface areas.

Bear in mind, while this guide provides a whole lot of thorough information, there's constantly even more to discover and understand. That's where Bish's recreational vehicle enters into the image. Our team of licensed recreational vehicle technicians is always on standby, happy to respond to any type of continuing to be concerns about photovoltaic panels you could have. Buttons Bish's motor home Web content Manager With over one decade in the recreational vehicle industry, Greg combines firsthand dealer experience with an enthusiasm for helping people find the best recreational vehicle for their journeys.

(Read why we transitioned from van life to Airstream life here!) Even with my restricted understanding of solar systems at the time, I knew it wouldn't amount to a lot. After inspecting it further, the reality was that it wasn't actually a system in all. A lot of travel trailers just aren't created for distributed camping off the whole lot, and Airstreams are no exemption.

Motorhome Repair Shops Orange, CA

Confronted with the limitations of these stock planetary systems, many RVers merely make use of gas or diesel-powered generators to maintain their batteries complemented while camping off-grid. Nonetheless, we chose at an early stage that we did not wish to take a trip with a generator. Our main objection was the incessant sound, yet generators have other downsides as well.

As you may anticipate, the initial choice was about a 3rd of the expense of alternative two, and the Do it yourself choice was regarding half the rate for both choices. At the time, the thought of mounting our very own solar system was a bit frustrating.

Rates can differ drastically depending on the dimension of your wanted system, and what you mean to power. Our 28 Airstream has actually restricted "property" on the roofing for solar panels, yet you can go rather insane with a 45 Fifth Wheel. After some to and fro, we determined to go with choice one and the DIY install alternative.

(Unsure what any of this means?! I had not been certain initially either, but I can ensure you that AM Solar does. They damage this information down way better than I ever before could, so look into their "Style Guides" area on their site for more information!)Switching to lithium batteries complicated the mount, however due to the fact that lithium batteries can be attracted down substantially further than lead acid batteries, it was definitely worth the initiative.

Rv Repair Service Near Me Orange, CA

I got ta be honest, when I first opened package of components from AM Solar I was overwhelmed with the thought of, "What the hell have I obtained myself right into?" It spent some time, once I laid out every one of the components and referenced the layout, I was able to cover my head around just how it all functioned.

It really did not take us very long to recognize that we probably should have gone with the extra robust system suggested by AM Solar. Under optimal sunlight conditions, our panels might keep our batteries topped off, yet a couple of days of cloud cover or rainfall and we would find ourselves needing to plug in.

I will certainly confess, I was a little anxious having their technologies evaluate my work, yet they offered me 2 thumbs up and informed me it was one of the better DIY installs they had seen. (RATING!) It was a wonderful pat on the back, and a good self-confidence boost leading into what would be an additional huge motor home project.

I had a lot even more confidence going right into this mount and I discovered myself truly appreciating the process. I didn't also mind piercing that dreadful opening via the roofing system of our Airstream! As of March 2023, we have actually had this upgraded system for greater than nine months and are impressed by how it has stayed up to date with our requirements.

Rv Delamination Repair Near Me Orange, CA

As you may expect, the very first option was regarding a third of the expense of option two, and the DIY option was regarding half the rate for both options. At the time, the idea of mounting our very own solar system was a little bit overwhelming.

Bear in mind that pricing can differ considerably depending on the size of your wanted system, and what you plan to power. Our 28 Airstream has limited "actual estate" on the roof covering for photovoltaic panels, however you can go rather insane with a 45 Fifth Wheel. After some back and forth, we determined to select option one and the DIY mount alternative.

(Not certain what any of this suggests?! I wasn't sure at initial either, but I can ensure you that AM Solar does. Switching to lithium batteries complicated the install, but since lithium batteries can be drawn down significantly further than lead acid batteries, it was absolutely worth the effort.

Rv Repair Service Near Me Orange, CA

I obtained ta be honest, when I initially opened up package of elements from AM Solar I was overwhelmed with the thought of, "What the heck have I obtained myself right into?" It took a while, once I outlined every one of the components and referenced the diagram, I had the ability to cover my head around exactly how all of it worked.

They also have a committed helpline for full-time RVers that required immediate support. Talk concerning customer care! It really did not take us extremely long to realize that we possibly should have opted for the extra robust system advised by AM Solar. Under ideal sunlight problems, our panels might maintain our batteries rounded off, however a few days of cloud cover or rainfall and we would certainly locate ourselves requiring to connect in.

I will admit, I was a little anxious having their technologies inspect my job, however they provided me two thumbs up and told me it was one of the far better do it yourself mounts they had seen. (RATING!) It was a great rub on the back, and a good self-confidence boost introducing what would certainly be one more large RV job.

OCRV Center

Address: 23281 La Palma Ave Yorba Linda, CA 92887Phone: (714) 909-1444

Email: [email protected]

OCRV Center

I had a whole lot even more self-confidence going into this set up and I found myself truly enjoying the procedure. I didn't also mind drilling that dreaded opening via the roofing of our Airstream! Since March 2023, we have actually had this upgraded system for even more than nine months and are impressed by how it has stayed on par with our demands.

Rv Repair Places Near Me Orange, CARv Repair And Service Near Me Orange, CA

Rv Service Repair Near Me Orange, CA

Rv Repair Service Near Me Orange, CA

Rv Ceiling Repair Orange, CA

Motorhome Service And Repair Near Me Orange, CA

Motorhome Refrigerator Repair Orange, CA

Rv Mechanics Near Me Orange, CA

Rv Ceiling Repair Orange, CA

Rv Repair Shops Near My Location Orange, CA

Best Rv Repair Near Me Orange, CA

Motorhome Service And Repair Near Me Orange, CA

Motorhome Refrigerator Repair Orange, CA

Camper Ac Repair Near Me Orange, CA

Rv Refrigerator Repair Near Me Orange, CA

Rv Ceiling Repair Orange, CA

Rv Service And Repair Near Me Orange, CA

Motorhome Generator Repair Near Me Orange, CA

Full Service Rv Repair Near Me Orange, CA

Rv Mechanics Near Me Orange, CA

Motorhome Generator Repair Near Me Orange, CA

Rv Service And Repair Near Me Orange, CA

Rv Repair Shops Near My Location Orange, CA

Rv Refrigerator Repair Near Me Orange, CA

Best Rv Repair Near Me Orange, CA

Rv Repair And Service Near Me Orange, CA

Motorhome Repair Shop Orange, CA

Motorhome Generator Repair Near Me Orange, CA

Rv Repair Services Near Me Orange, CA

Rv Repair And Service Near Me Orange, CA

Motorhome Repair Near Me Orange, CA

Camper Ac Repair Near Me Orange, CA

Rv Repair Centers Near Me Orange, CA

Rv Repair Centers Near Me Orange, CA

Best Rv Repair Near Me Orange, CA

Rv Repair Places Near Me Orange, CA

Motorhome Repair Shops Orange, CA

Best Rv Repair Near Me Orange, CA

Motorhome Generator Repair Near Me Orange, CA

Camper Ac Repair Near Me Orange, CA

Motorhome Awning Repair Orange, CA

Rv Service Repair Near Me Orange, CA

Full Service Rv Repair Near Me Orange, CA

Motorhome Repair Service Orange, CA

Rv Refrigerator Repair Near Me Orange, CA

Motorhome Refrigerator Repair Orange, CA

Rv Floor Repair Near Me Orange, CA

Rv Plumbing Repair Near Me Orange, CA

Motorhome Refrigerator Repair Orange, CA

Full Service Rv Repair Near Me Orange, CA

Rv Repairs Near Me Orange, CA

Motorhome Repair Near Me Orange, CA

Motorhome Service And Repair Near Me Orange, CA

Rv Repair And Service Near Me Orange, CA

Motorhome Service And Repair Near Me Orange, CA

Motorhome Service And Repair Near Me Orange, CA

Rv Delamination Repair Near Me Orange, CA

Rv Repair Services Near Me Orange, CA

Rv Solar Installation Orange, CA

Rv Ceiling Repair Orange, CA

Motorhome Repair Service Orange, CA

Motorhome Awning Repair Orange, CA

Full Service Rv Repair Near Me Orange, CA

Rv Floor Repair Near Me Orange, CA

Rv Repair Service Near Me Orange, CA

Rv Repair Services Near Me Orange, CA

Rv Delamination Repair Near Me Orange, CA

Rv Delamination Repair Near Me Orange, CA

Rv Repair In My Area Orange, CA

Rv Delamination Repair Near Me Orange, CA

Motorhome Awning Repair Orange, CA

Rv Delamination Repair Near Me Orange, CA

Best Rv Repair Near Me Orange, CA

Rv Repairs Near Me Orange, CA

Rv Mechanics Near Me Orange, CA

Rv Generator Repair Orange, CA

Full Service Rv Repair Near Me Orange, CA

Rv Mechanics Near Me Orange, CA

Near Seo Marketing Orange, CA

Near Seo Citations Orange, CA

OCRV Center

Table of Contents

- – Motorhome Repair Shop Orange, CA

- – OCRV Center

- – Rv Service And Repair Near Me Orange, CA

- – Motorhome Repair Service Orange, CA

- – Rv Mechanics Near Me Orange, CA

- – Full Service Rv Repair Near Me Orange, CA

- – Best Rv Repair Near Me Orange, CA

- – Rv Generator Repair Orange, CA

- – Rv Ceiling Repair Orange, CA

- – Motorhome Repair Shops Orange, CA

- – Rv Repair Service Near Me Orange, CA

- – Rv Delamination Repair Near Me Orange, CA

- – Rv Repair Service Near Me Orange, CA

- – OCRV Center

Latest Posts

Tankless Hot Water Heater Installation Near Me 4s Ranch San Diego

Plumber Near Me Clogged Toilet Mira Mesa

Toilet Plumbing Near Me Miramar Ranch North

More

Latest Posts

Tankless Hot Water Heater Installation Near Me 4s Ranch San Diego

Plumber Near Me Clogged Toilet Mira Mesa

Toilet Plumbing Near Me Miramar Ranch North