All Categories

Featured

Table of Contents

- – Rv Plumbing Repair Near Me Eastvale, CA

- – OCRV Center

- – Rv Service And Repair Near Me Eastvale, CA

- – Rv Service Repair Near Me Eastvale, CA

- – Motorhome Awning Repair Eastvale, CA

- – Rv Solar Panel Installation Eastvale, CA

- – Rv Solar Panel Installation Eastvale, CA

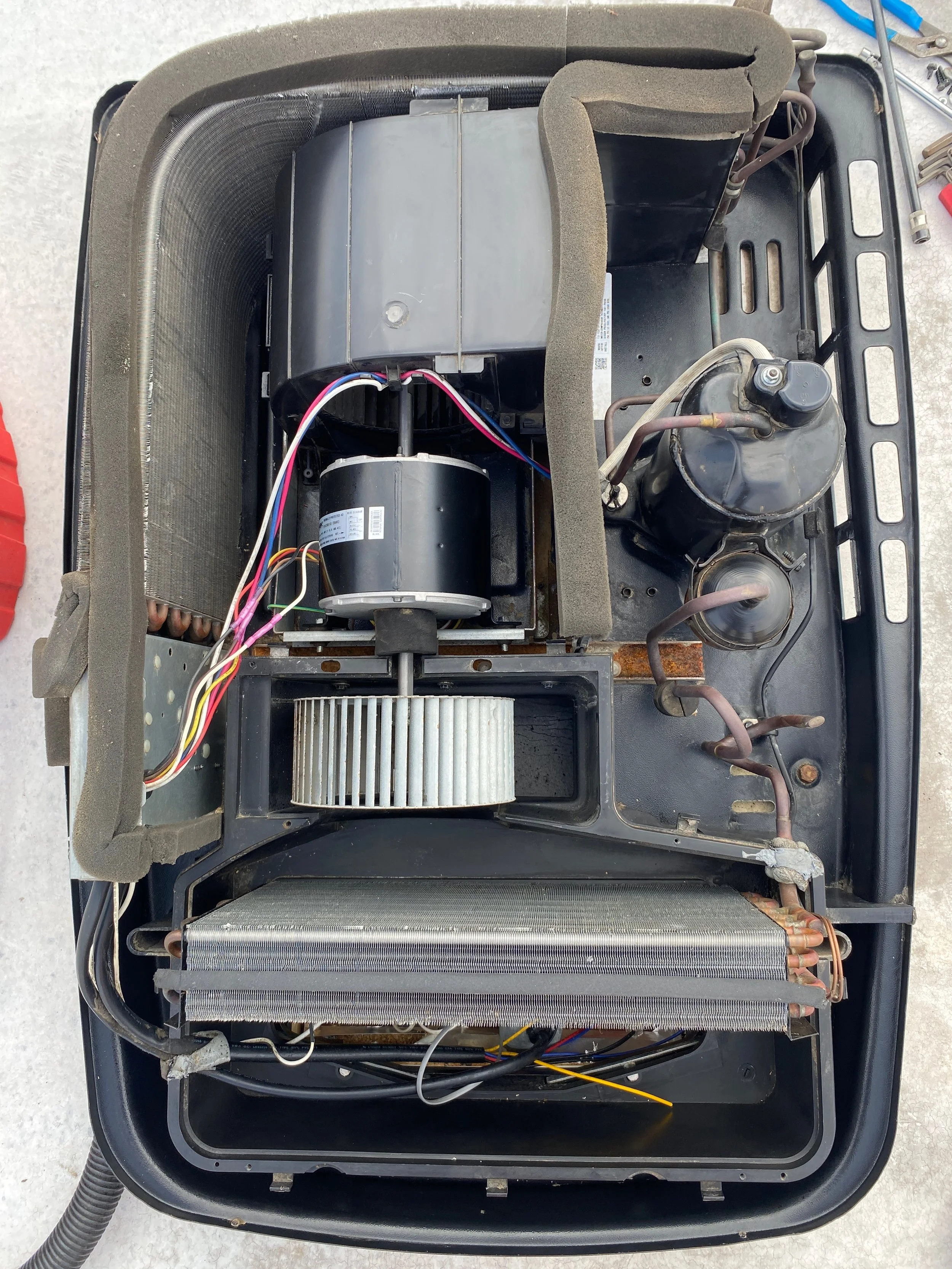

- – Camper Ac Repair Near Me Eastvale, CA

- – Motorhome Generator Repair Near Me Eastvale, CA

- – Rv Repair Service Near Me Eastvale, CA

- – Rv Mechanics Near Me Eastvale, CA

- – Rv Floor Repair Near Me Eastvale, CA

- – Rv Repairs Near Me Eastvale, CA

- – Best Rv Repair Near Me Eastvale, CA

- – Rv Service Repair Near Me Eastvale, CA

- – OCRV Center

Rv Plumbing Repair Near Me Eastvale, CA

Based Upon Simply Skyrocketing 2025-06-19 Trustindex confirms that the initial resource of the testimonial is Google. Came down to extremely rural off grid location following day after called. Wonder nowadays. A lot of men were claiming "week or two possibly". Obtained the awning components we required. Estimated 3 hours. Did it in two and billed us 2.

Andrew is so respectful, kind, professional and takes the time to explain every little thing he is doing and why. Also if it is not related to the component he is working on.

Rv Service And Repair Near Me Eastvale, CA

No better area to turn to for Recreational vehicle repair work and upgrades. Erin Coons 2025-03-29 Trustindex validates that the initial resource of the evaluation is Google.

I have no complaints, and all of the appreciation for this business. Thank you again to Andrew deborah metcalf 2025-02-25 Trustindex confirms that the original resource of the review is Google. extremely knowlegable, extremely profesional and really straightforward would recomend them every single time. scott coalter 2025-02-11 Trustindex validates that the initial source of the review is Google.

Drove to us, detected the problem, lent us a space heating unit given that a component required to be gotten for ours, and gotten and installed the furnace motherboard. Extremely timely with the repair work. Kathy Baker 2024-11-10 Trustindex confirms that the original resource of the testimonial is Google. Emergency of no water in our recreational vehicle, huge leak so shut off up until Andrew got here.

Grady Colson 2024-09-28 Trustindex confirms that the original resource of the review is Google. As a brand-new RV proprietor, I have actually relied on T&A Mobile Recreational Vehicle Repair work for the past year.

Rv Service Repair Near Me Eastvale, CA

Free "Roofing System & Sidewall Examination" with Service Charge *, upon request. All solutions go through problems.

Undesirable mildew and mold and mildew smells rise from your air conditioner vents. The AC functions only while the vehicle is in movement. Also at the highest possible fan setting, there's weak air movement. Water condenses or leaks onto your foot while driving. Don't delay! If your auto's air conditioning isn't running at peak effectiveness, a browse through to Nor Cal Performance is a smart action.

If your automobile's AC begins to shed its cooling efficiency, consider a freon recharge. This fast and affordable service recovers trendy air, giving relief from the heat. Know that if there's a freon leakage, maybe due to a harmed pipe or seal, which might call for more substantial repair services.

Motorhome Awning Repair Eastvale, CA

The Thermal Development Valve or Orifice Tube is necessary for managing your air conditioning system's pressure and temperature, regulating the circulation of refrigerant right into the evaporator. Proper equilibrium stops dampness accumulation, vital for maintaining your vehicle's air conditioning effectiveness. Never ever, at the very least not in the means you think about your oil being altered.

It is recommended to have your engine running while charging your automobile's A/C system. A refrigerant leak can lead to a loss of pressure in the Air conditioning system, resulting in a failing to generate chilly air.

Schedule your automobile AC repair service visit with Neither Cal Performance today! Discover More Concerning AC Repair Service Services At Neither Cal Efficiency in West Sacramento.

Unpleasant mildew and mold smells originate from your A/c vents. The A/c functions only while the lorry is in motion. If your vehicle's Air conditioning isn't operating at peak efficiency, a browse through to Neither Cal Efficiency is a smart action.

Rv Solar Panel Installation Eastvale, CA

If your automobile's AC starts to lose its cooling effectiveness, consider a freon recharge. This quick and cost-effective option restores great air, providing alleviation from the warmth. Understand that if there's a freon leakage, it could be as a result of a damaged tube or seal, which could need extra considerable repairs.

The Thermal Growth Valve or Orifice Tube is important for managing your AC system's stress and temperature level, regulating the circulation of cooling agent right into the evaporator. Proper equilibrium prevents moisture accumulation, crucial for keeping your vehicle's air conditioner effectiveness. Never, a minimum of not in the method you assume of your oil being changed.

Inspect your guidebook for the specific total up to stay clear of overfilling. It is recommended to have your engine running while recharging your cars and truck's A/C system. This is necessary as the A/C compressor, powered by the engine, should be active to assist in correct cooling agent flow and ensure a reliable recharge. A refrigerant leak can cause a loss of stress in the air conditioner system, causing a failure to produce cool air.

Arrange your auto A/c repair work consultation with Neither Cal Efficiency today! Discover Much More Concerning AC Repair Provider At Nor Cal Performance in West Sacramento.

Rv Solar Panel Installation Eastvale, CA

Unpleasant mold and mold and mildew smells originate from your a/c vents. The AC works just while the lorry remains in activity. Also at the greatest fan setup, there's weak airflow. Water condenses or drips onto your foot while driving. Do not delay! If your cars and truck's air conditioning isn't operating at peak efficiency, a check out to Neither Cal Efficiency is a wise step.

If your lorry's AC starts to lose its cooling effectiveness, think about a freon recharge - Motorhome Repair Shop Eastvale. This quick and cost-effective solution brings back cool air, offering relief from the warm. Understand that if there's a freon leakage, it might be because of a damaged hose or seal, which might require much more extensive fixings

The Thermal Growth Shutoff or Orifice Tube is necessary for regulating your air conditioning system's stress and temperature, managing the circulation of cooling agent right into the evaporator. Appropriate equilibrium avoids dampness accumulation, crucial for preserving your lorry's air conditioner efficiency. Never, at least not in the way you think about your oil being transformed.

Examine your handbook for the specific total up to avoid overfilling. It is recommended to have your engine running while charging your auto's A/C system. This is crucial as the A/C compressor, powered by the engine, have to be active to facilitate correct refrigerant blood circulation and guarantee a reliable recharge. A cooling agent leak can lead to a loss of stress in the a/c system, leading to a failing to generate cool air.

Camper Ac Repair Near Me Eastvale, CA

Arrange your automobile AC repair consultation with Nor Cal Efficiency today! Discover A Lot More Regarding Air Conditioner Repair Work Services At Nor Cal Efficiency in West Sacramento.

Undesirable mold and mold and mildew smells rise from your air conditioning vents. The AC works just while the vehicle remains in movement. Even at the highest possible fan setting, there's weak air movement. Water condenses or trickles onto your foot while driving. Don't delay! If your auto's AC isn't running at peak efficiency, a browse through to Nor Cal Efficiency is a smart move.

If your lorry's AC starts to lose its cooling efficiency, think about a freon recharge. This fast and affordable remedy brings back trendy air, supplying remedy for the heat. Know that if there's a freon leakage, it might be because of a damaged hose pipe or seal, which could call for extra extensive fixings.

Motorhome Generator Repair Near Me Eastvale, CA

The Thermal Development Valve or Orifice Tube is crucial for managing your AC system's pressure and temperature level, controlling the flow of cooling agent into the evaporator. Correct equilibrium stops dampness build-up, vital for preserving your vehicle's air conditioning effectiveness. Never, a minimum of not in the method you consider your oil being altered.

It is encouraged to have your engine running while recharging your automobile's A/C system. A refrigerant leak can lead to a loss of stress in the A/c system, resulting in a failure to create cold air.

Schedule your vehicle Air conditioner repair service appointment with Nor Cal Efficiency today! Discover A Lot More Regarding Air Conditioner Fixing Solutions At Nor Cal Performance in West Sacramento.

Rv Repair Service Near Me Eastvale, CA

Unpleasant mold and mold odors emanate from your Air conditioner vents. The AC functions only while the car is in motion. If your auto's Air conditioner isn't operating at peak performance, a check out to Nor Cal Efficiency is a sensible move.

If your vehicle's a/c starts to shed its cooling performance, take into consideration a freon recharge. This fast and cost-effective option recovers amazing air, supplying remedy for the warm. Know that if there's a freon leak, it might be because of a harmed hose or seal, which could call for much more extensive fixings.

The Thermal Development Shutoff or Orifice Tube is important for managing your AC system's pressure and temperature level, managing the circulation of cooling agent into the evaporator. Correct balance stops moisture accumulation, essential for keeping your vehicle's a/c efficiency. Never, at least not in the means you consider your oil being transformed.

Rv Mechanics Near Me Eastvale, CA

It is advised to have your engine running while reenergizing your car's A/C system. A cooling agent leakage can lead to a loss of stress in the Air conditioning system, resulting in a failing to produce cold air.

It is critical to examine the system for leakages and deal with any kind of problems prior to proceeding with a recharge. Schedule your vehicle AC repair consultation with Neither Cal Efficiency today! Our expert professionals are outfitted to swiftly identify and settle all your a/c concerns. Discover More Concerning AC Fixing Solutions At Neither Cal Performance in West Sacramento.

Rv Floor Repair Near Me Eastvale, CA

Undesirable mold and mold and mildew smells originate from your A/c vents. The A/c functions just while the car is in motion. If your car's AC isn't running at peak performance, a check out to Nor Cal Performance is a smart relocation.

If your automobile's AC begins to lose its cooling effectiveness, consider a freon recharge. This quick and cost-efficient remedy recovers great air, supplying relief from the warm. Be aware that if there's a freon leakage, maybe due to a damaged pipe or seal, which might require a lot more comprehensive repair services.

The Thermal Expansion Valve or Orifice Tube is crucial for regulating your AC system's stress and temperature, regulating the circulation of cooling agent right into the evaporator. Correct balance protects against dampness build-up, critical for maintaining your lorry's air conditioner performance. Never ever, at least not in the means you consider your oil being transformed.

Rv Repairs Near Me Eastvale, CA

It is advised to have your engine running while charging your cars and truck's A/C system. A cooling agent leak can lead to a loss of stress in the A/c system, resulting in a failing to generate cold air.

Schedule your vehicle Air conditioner fixing visit with Nor Cal Efficiency today! Discover A Lot More About Air Conditioner Fixing Services At Neither Cal Efficiency in West Sacramento.

Unpleasant mold and mold and mildew smells emanate from your a/c vents. The air conditioning functions just while the automobile is in activity. Also at the highest follower setup, there's weak airflow. Water condenses or trickles onto your foot while driving. Do not delay! If your cars and truck's a/c isn't running at peak performance, a visit to Nor Cal Efficiency is a smart action.

Best Rv Repair Near Me Eastvale, CA

If your vehicle's air conditioner begins to shed its cooling effectiveness, consider a freon recharge. This quick and cost-efficient solution brings back awesome air, offering remedy for the heat. Understand that if there's a freon leak, maybe because of a damaged hose pipe or seal, which may need more extensive repairs.

The Thermal Development Shutoff or Orifice Tube is vital for managing your a/c system's pressure and temperature, managing the circulation of refrigerant into the evaporator. Proper balance prevents wetness accumulation, essential for keeping your lorry's air conditioner effectiveness. Never ever, at the very least not in the method you consider your oil being altered.

Rv Service Repair Near Me Eastvale, CA

It is advised to have your engine running while charging your cars and truck's A/C system. A refrigerant leakage can lead to a loss of stress in the Air conditioning system, resulting in a failing to produce cold air.

OCRV Center

Address: 23281 La Palma Ave Yorba Linda, CA 92887Phone: (714) 909-1444

Email: [email protected]

OCRV Center

It is essential to examine the system for leakages and address any kind of concerns before continuing with a recharge. Arrange your auto air conditioner repair appointment with Neither Cal Performance today! Our expert technicians are geared up to promptly diagnose and solve all your air conditioning problems. Discover Extra Concerning Air Conditioner Repair Service Solutions At Neither Cal Efficiency in West Sacramento.

Motorhome Repair Service Eastvale, CARv Solar Panel Installation Eastvale, CA

Rv Service Repair Near Me Eastvale, CA

Full Service Rv Repair Near Me Eastvale, CA

Rv Refrigerator Repair Near Me Eastvale, CA

Rv Solar Panel Installation Eastvale, CA

Rv Repair And Service Near Me Eastvale, CA

Best Rv Repair Near Me Eastvale, CA

Motorhome Refrigerator Repair Eastvale, CA

Rv Repair Places Near Me Eastvale, CA

Rv Plumbing Repair Near Me Eastvale, CA

Rv Repair Places Near Me Eastvale, CA

Motorhome Generator Repair Near Me Eastvale, CA

Motorhome Awning Repair Eastvale, CA

Motorhome Repair Near Me Eastvale, CA

Rv Repair Places Near Me Eastvale, CA

Rv Service Repair Near Me Eastvale, CA

Rv Mechanics Near Me Eastvale, CA

Rv Repair Places Near Me Eastvale, CA

Best Rv Repair Near Me Eastvale, CA

Rv Repairs Near Me Eastvale, CA

Rv Repair And Service Near Me Eastvale, CA

Motorhome Generator Repair Near Me Eastvale, CA

Rv Generator Repair Eastvale, CA

Rv Repair Services Near Me Eastvale, CA

Rv Repair Places Near Me Eastvale, CA

Motorhome Repair Near Me Eastvale, CA

Rv Mechanics Near Me Eastvale, CA

Rv Repairs Near Me Eastvale, CA

Rv Floor Repair Near Me Eastvale, CA

Rv Plumbing Repair Near Me Eastvale, CA

Full Service Rv Repair Near Me Eastvale, CA

Rv Refrigerator Repair Near Me Eastvale, CA

Rv Repair Centers Near Me Eastvale, CA

Rv Repair In My Area Eastvale, CA

Motorhome Service And Repair Near Me Eastvale, CA

Rv Service And Repair Near Me Eastvale, CA

Rv Generator Repair Eastvale, CA

Motorhome Service And Repair Near Me Eastvale, CA

Motorhome Repair Shops Eastvale, CA

Motorhome Repair Shops Eastvale, CA

Best Rv Repair Near Me Eastvale, CA

Rv Delamination Repair Near Me Eastvale, CA

Rv Service And Repair Near Me Eastvale, CA

Motorhome Repair Shop Eastvale, CA

Rv Generator Repair Eastvale, CA

Rv Repair Service Near Me Eastvale, CA

Motorhome Repair Near Me Eastvale, CA

Rv Ceiling Repair Eastvale, CA

Motorhome Generator Repair Near Me Eastvale, CA

Rv Repair Service Near Me Eastvale, CA

Rv Repairs Near Me Eastvale, CA

Rv Ceiling Repair Eastvale, CA

Rv Floor Repair Near Me Eastvale, CA

Motorhome Repair Shops Eastvale, CA

Motorhome Repair Service Eastvale, CA

Rv Repair Service Near Me Eastvale, CA

Rv Solar Installation Eastvale, CA

Motorhome Service And Repair Near Me Eastvale, CA

Motorhome Service And Repair Near Me Eastvale, CA

Motorhome Repair Shop Eastvale, CA

Camper Ac Repair Near Me Eastvale, CA

Rv Mechanics Near Me Eastvale, CA

Rv Solar Panel Installation Eastvale, CA

Rv Repair In My Area Eastvale, CA

Rv Solar Installation Eastvale, CA

Rv Solar Panel Installation Eastvale, CA

Rv Solar Installation Eastvale, CA

Rv Repair In My Area Eastvale, CA

Rv Service And Repair Near Me Eastvale, CA

Rv Repair Centers Near Me Eastvale, CA

Motorhome Repair Near Me Eastvale, CA

Rv Repair In My Area Eastvale, CA

Camper Ac Repair Near Me Eastvale, CA

Rv Refrigerator Repair Near Me Eastvale, CA

Motorhome Generator Repair Near Me Eastvale, CA

Rv Service Repair Near Me Eastvale, CA

Rv Refrigerator Repair Near Me Eastvale, CA

Finding A Local Seo Service Eastvale, CA

Close To Me Seo Services Near Me Eastvale, CA

OCRV Center

Table of Contents

- – Rv Plumbing Repair Near Me Eastvale, CA

- – OCRV Center

- – Rv Service And Repair Near Me Eastvale, CA

- – Rv Service Repair Near Me Eastvale, CA

- – Motorhome Awning Repair Eastvale, CA

- – Rv Solar Panel Installation Eastvale, CA

- – Rv Solar Panel Installation Eastvale, CA

- – Camper Ac Repair Near Me Eastvale, CA

- – Motorhome Generator Repair Near Me Eastvale, CA

- – Rv Repair Service Near Me Eastvale, CA

- – Rv Mechanics Near Me Eastvale, CA

- – Rv Floor Repair Near Me Eastvale, CA

- – Rv Repairs Near Me Eastvale, CA

- – Best Rv Repair Near Me Eastvale, CA

- – Rv Service Repair Near Me Eastvale, CA

- – OCRV Center

Latest Posts

Fairbanks Ranch Tankless Water Heater Installation

Water Heater Install Leucadia

Toilet Installation Del Mar

More

Latest Posts

Fairbanks Ranch Tankless Water Heater Installation

Water Heater Install Leucadia

Toilet Installation Del Mar